- Construction and expansion of wind and hydropower plants

- Development of solar energy

- Development of geothermal energy

- Development of hydrogen energy

- Expansion of international cooperation

Address of “Samruk-Energy” JSC head office:

010000, Astana c., 15A, Kabanbay batyr ave., Block B, "Q" business center

For documentation support inquiries

+ 7 (7172) 55-31-28

+7 (7172) 55-30-21

e-mail:

Press Secretary

+ 7 (7172) 55-30-62

Human Resources Department

+7 (7172) 55-30-25, +7 (7172) 69-24-38 (for job inquiries)

Procurement Department

+ 7 (7172) 69-24-23

Accounting and Tax Department

+ 7 (7172) 55-30-40

Corporate Governance and Sustainable Development Department

+7(7172) 55-30-20

Coal

companies

Generation companies

Distribution companies

Hydropower companies

HPP

Renewables companies

tab

Our approach

According to the Development Strategy of “Samruk-Energy” JSC for 2024-2033, reduction of net carbon footprint is among strategic goals of the Company, and one of key development priorities is the consistency of environmental (E), social (S) and governance (G) principles. The Company has sought to contribute to the structure of the national economy, promoting the development of renewable energy sources, maximum reduction of air emissions and the improvement of the ecosystem. The Company’s primary concern is not only to ensure survival in high-risk conditions through proper forecasting and planning, but also to turn risks into opportunities and prepare for an unforeseen future.

The main documents of “Samruk-Energy” JSC that ensure the implementation of sustainable development principles are the Sustainable Development Guidelines, the Corporate Governance Code, Corporate governance system policy, Human Resources Policy and other internal regulatory documents.

In accordance with the Corporate Governance Code of “Samruk-Energy” JSC, we comply with the following principles in sustainable development:

- Openness

- Accountability

- Transparency

- Ethical behavior

- Respect for the interests of stakeholders

- Legality

- Respect for human rights

- Zero tolerance against corruption

- Inadmissibility of conflicts of interest

- Personal example

JSC “Samruk-Energy” launches a project on climate risk management in accordance with TCFD (IFRS S2) recommendations

In 2025, JSC “Samruk-Energy” commenced the implementation of a project aimed at adopting best international practices for climate risk management and disclosure in line with the standards of the Task Force on Climate-related Financial Disclosures (TCFD) and IFRS S2.

The project is designed to enhance transparency and strengthen the trust of investors, lenders, and other stakeholders, as well as to meet the Company’s commitments within its cooperation with international financial institutions.

Key priorities of the project:

- Strengthening and further integrating the climate agenda into the corporate governance system;

- Refining scenario analysis of transition and physical climate risks, as well as pathways toward achieving carbon neutrality;

- Quantitative assessment of the impact of climate risks on the Company’s strategy and financial performance;

- Development of practical methodologies for integrating climate risks into the management, planning, and reporting processes of JSC “Samruk-Energy”;

- Disclosure of climate-related information in accordance with international requirements.

What will be achieved during project implementation:

Strategy: Evaluation and update of long-term decarbonization and carbon footprint reduction targets, aligned with national and international commitments.

Governance: Clarification of the roles and responsibilities of the governing and executive bodies in climate management to ensure systematic control and monitoring.

Risks and Opportunities: Conducting scenario assessments of climate-related risks and opportunities and integrating them into strategic and investment planning.

Metrics and Targets: Climate data disclosure complemented by an assessment of its strategic, financial, and operational implications.

Disclosure: Preparation of a climate-related disclosure draft for inclusion in the integrated annual report.

Expected outcomes:

Implementation of the project will enable the Company to ensure compliance with international standards, enhance transparency and climate risk management, and strengthen stakeholder confidence. The adoption of TCFD-aligned disclosures will contribute to the development of a sustainable business model that takes into account long-term climate challenges and the expectations of investors and other stakeholders.

tab

Sustainable development goals

“Samruk-Energy” JSC, while incorporating sustainable development principles into its business, is committed to 17 Sustainable Development Goals (hereinafter - SDG). The company recognizes that the environmental and social issues that each SDG addresses are relevant and influences any organization.

A detailed description about SDG applicable to the Company is presented on the company’s website in “To shareholders and investors” section, Annual Reports about the Company’s operating results.

Certificates confirming compliance with the requirements of international standards: ISO 9001, ISO 14001, ISO 45001, ISO 5000, ISO 37001. 1, ISO 37001.

In 2024, the external supervisory audit of the corporate management system was successfully completed in compliance with international standards ISO 9001, ISO 14001, ISO 45001, ISO 50001, and ISO 37001. These international standards apply to LLP "Ekibastuz GRES-1 named after B. Nurzhanov," JSC "Ekibastuz GRES-2 Station," JSC "Almaty Power Stations," JSC "Moynak HPP," LLP "Samruk Green Energy," JSC "Alatau Zharyk Company," LLP "AlmatyEnergoSbyt," JSC "Shardara HPP," LLP "First Wind Power Plant," and the corporate center of JSC "Samruk-Energo."

tab1

Environmental management approach

As Kazakhstan’s leading energy company Samrurk-Energy JSC places environmental protection at the core of its corporate responsibility. We are committed to aligning our operations with national environmental legislation, the ISO 14001 international standard, and recognised best practices in sustainable development, with the overarching goal of minimising our environmental footprint.

Our environmental management activities are focused on the following priority areas:

● preventing and reducing environmental impact, including improving air quality, responsible waste management, and sustainable water resource use;

● contributing to climate change mitigation efforts;

● conserving and efficiently utilising energy resources;

● implementing effective environmental monitoring and impact assessments;

● preserving natural landscapes and biodiversity.

To ensure systematic and transparent environmental governance, the Company has adopted a number of key internal documents:

● Corporate Management System Policy;

● Corporate Environmental Protection Management Standard for the Samruk-Energy Group of Companies;

● Emergency Environmental Response and Management Guidelines;

● Environmental Safety Programme of Samruk-Energy Group of Companies.

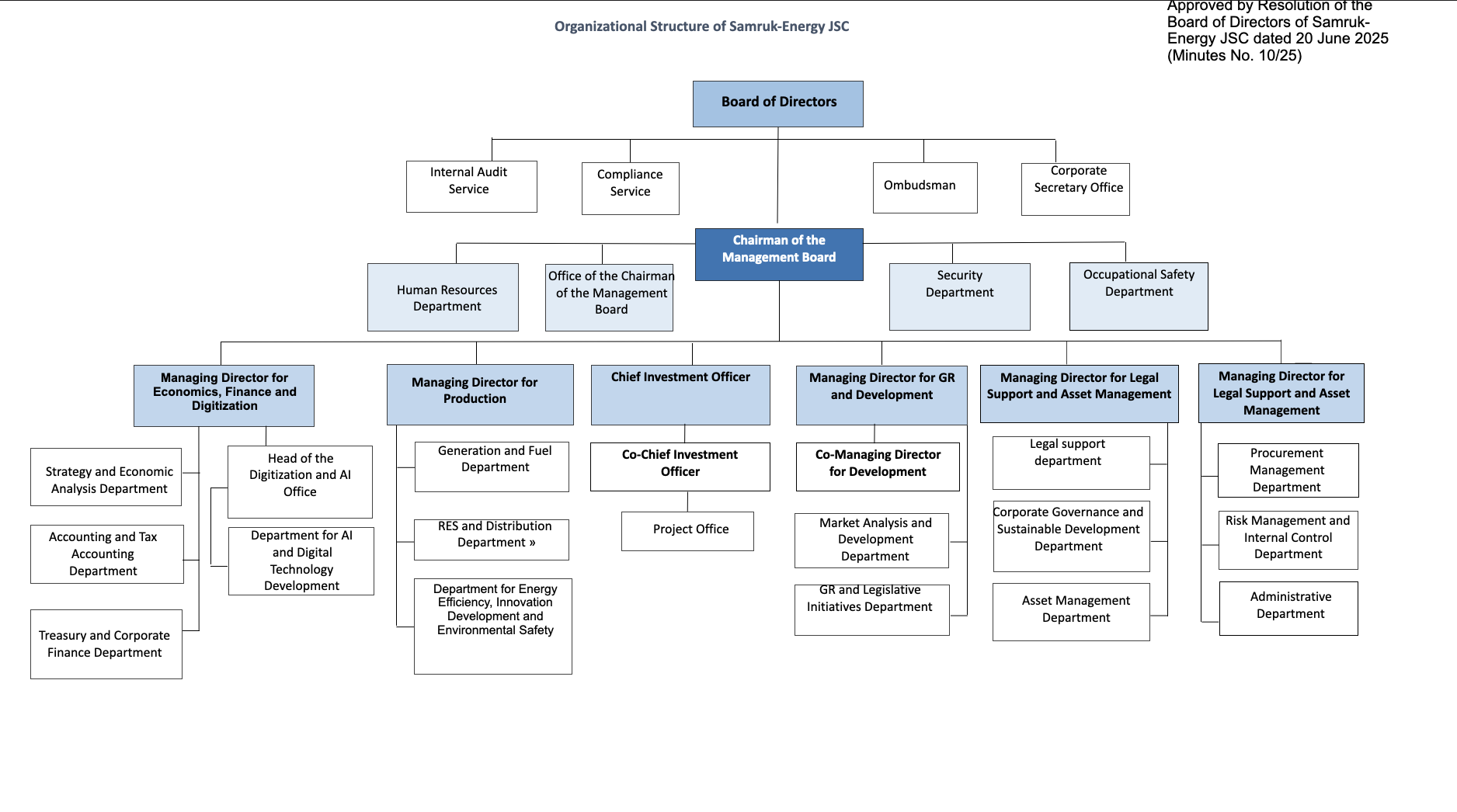

Environmental protection is fully embedded in the Company’s corporate governance structure. The senior executive team is accountable for the implementation of the Company’s environmental commitments, targets, and performance indicators. The Board of Directors is responsible for approving the environmental strategy and associated policies. Day-to-day oversight of environmental initiatives is carried out by the Department for Energy Efficiency, Innovation Development and Environmental Safety of Samruk-Energy JSC. Within the Group’s subsidiaries, dedicated environmental units are in place to implement corporate policies and strategies, and to ensure that contractors and business partners comply with the Company’s environmental standards.

Environmental safety programme of Samruk-Energy group of companies

To support the achievement of its strategic objectives through to 2033, Samruk-Energy’s Board of Directors approved the Group’s Environmental Safety Programme in 2024. This Programme serves as the core planning tool for the Group’s environmental activities, setting out clear goals and measures aimed at achieving environmental sustainability and enhancing corporate social responsibility.

The Programme is long-term and target-oriented, providing a framework for integrating planned initiatives into the Group’s long-term, medium-term, and operational planning documents. The implementation period spans from 2024 to 2033.

Precautionary principles

When planning and executing projects, Samruk-Energy JSC applies a precautionary approach, placing strong emphasis on the assessment of potential environmental impacts and associated risks. In line with the Company’s internal standards, each project undergoes a rigorous risk assessment process, including the analysis of environmental impact and potential long-term consequences. These assessments are carried out with the involvement of qualified experts, in accordance with internal regulations governing risk management for investment projects.

The Company implements both routine and capital-intensive environmental measures aimed at mitigating environmental risks. Continuous monitoring of effectiveness is conducted, along with ongoing improvement of tools for environmental risk assessment and management.

To strengthen accountability and employee motivation in reducing environmental risks, Samruk-Energy JSC has introduced environmental Key Performance Indicators (KPIs), enabling more effective management of environmental safety and the achievement of strategic targets.

Monitoring and transparency

To maintain a high standard of environmental accountability, the Company regularly discloses detailed reports on its environmental activities. Quarterly reports are submitted to the Management Board and the dedicated Committee for Safety, Occupational Health, and Environmental Protection. An annual report, the “Environmental Protection Performance Report”, is also submitted to the Board of Directors of Samruk-Energy JSC.

In 2024, the Samruk-Energy Group successfully passed an external surveillance audit confirming the compliance of its corporate management system with the requirements of international standards ISO 9001, ISO 14001, ISO 45001, ISO 50001, and ISO 37001.

In the same year, the Group successfully implemented 94% of its planned environmental protection activities, which covered air, water and land protection, as well as the conservation of flora, fauna, and biodiversity.

A key achievement was the implementation of an automated emissions monitoring system at ESDPP-2 JSC and APP JSC (CHP-1 and the Western Thermal Complex), as well as at Bogatyr Komir LLP (for the discharge of drainage and wastewater into the Akbidaik storage lake), with data transmitted every 20 minutes in real time to the National Database on the State of the Environment and Natural Resources of the Republic of Kazakhstan (NDSENR RK).

As part of the implementation of the 2024 Action Plan for Environmental Management within the Samruk-Energy Group of Companies, a number of cultural, educational, and environmental activities were carried out among employees of subsidiaries to mark World Environment Day, celebrated annually on June 5. Key initiatives included:

● Employees of SDPP-2 JSC organised an environmental event — plogging — aimed at preserving the environment and fostering a responsible attitude towards nature;

● Environmental specialists from the production departments and the head office of APP JSC conducted the “#Together – Clean Mountains” campaign in the Butakovka Gorge, which resulted in the collection of 18 bags (160 litres each) of waste;

● At ESDPP-1 LLP, a team-building event entitled “Green Unity” was held for power plant staff to promote environmental awareness and responsibility for nature conservation;

● At Bogatyr Komir LLP, a video and children’s drawing contest was held on the theme of “World Environment Day”;

● A range of thematic events and awareness campaigns were conducted at the enterprises of AZhC JSC, Shardarinsk HPP JSC, Moynak HPP JSC, Ust-Kamenogorsk HPP LLP, Shulbinsk HPP LLP, and First Wind Power Plant LLP, aimed at promoting environmentally conscious behavior and fostering aimed at promoting environmentally responsible behavior and fostering a culture of environmental awareness among employees.

Participation of Samruk-Energy employees in the citywide cleanup campaign

As part of the national environmental campaign Taza Kazakhstan, held in Astana in April 2024, the team of Samruk-Energy JSC actively participated in a citywide cleanup initiative. The primary objective of the event was to raise environmental awareness and promote the importance of environmental protection.

Company employees cleaned up the Energy Workers’ Alley, which had been planted by Samruk-Energy JSC to mark the 15th anniversary of the Samruk-Kazyna Fund. This event served as a meaningful contribution to improving the city’s environmental condition and once again underscored the Company’s commitment to sustainable development and environmental stewardship.

We maintain an ongoing dialogue with stakeholders on environmental issues. This helps us track the effectiveness of decisions and initiatives implemented, as well as identify and reassess environmental risks.

In 2024, the Company conducted public hearings on four projects, all of which received positive expert opinions.

In line with the principles of transparency and accountability, Samruk-Energy JSC organizes meetings, press conferences, and roundtable discussions to address environmental topics with representatives of the public, media, volunteer groups, and non-profit organizations. These initiatives involve the Company’s senior executives as well as the leadership of its subsidiaries.

Environmental protection expenditures

Under the 2024 Environmental Management Action Plan for the Samruk-Energy Group of Companies, as well as the Environmental Action Plans of its subsidiaries coordinated with the national environmental authority, 94% of the planned environmental protection measures were completed. A total of KZT 14.416 billion was utilized out of the allocated KZT 16.192 billion. Key measures aimed at reducing environmental impact and improving ecological performance included:

● Equipment modernization – overhaul of boiler burners and reconstruction of electrostatic precipitators to reduce dust emissions;

● Industrial process optimization – repair of the closed-loop production water system (dredge system), and maintenance of dust and gas cleaning units;

● Systemic pollution control measures – introduction of automated pollutant emissions monitoring systems and dust suppression measures at ash disposal sites;

● Sustainable waste management – waste disposal and the placement of overburden materials in temporary internal dumps, which will reduce the volume of external dumps by 69.511 million tons;

● Water conservation and wastewater treatment – maintenance of systems for the collection and treatment of stormwater and meltwater;

● Landscaping and greening – expansion of green spaces across production sites;

● Improved equipment reliability – repair of components and optimization of equipment operation modes in accordance with technical specifications.

Samruk-Energy JSC’s investments in environmental protection initiatives, KZT billion

|

Indicator |

2022 |

2023 |

2024 |

|

Expenditures on environmental protection initiatives |

7,1 |

24,4 |

14,4 |

We also paid over KZT 9 billion in regulatory emission charges (environmental tax).

Environmental benchmarking

Environmental benchmarking is a tool for assessing and managing the environmental performance of Samruk-Energy JSC by comparing its own indicators with the results of leading companies in the sector. This approach facilitates the adoption of best international practices in environmental management and sustainable development. The current analysis uses publicly available data for 2022–2024:

The following indicators were defined for benchmarking:

- freshwater use for technological and domestic drinking purposes;

- direct (Scope 1) and indirect (Scope 2) greenhouse gas (GHG) emissions.

To identify environmental trends, the largest energy companies in Kazakhstan and globally were analyzed, namely:

- ERG;

- CAEPCO JSC;

- KKS LLP;

- Enel Group;

- Inter RAO PJSC;

- RusHydro PJSC.

Production figures*

|

Company |

2022 |

2023 |

2024 |

|||

|

Electricity generation, bn.kWh |

Installed capacity, GW |

Electricity generation, bn.kWh |

Installed capacity, GW |

Electricity generation, bn.kWh |

Installed capacity, GW |

|

|

Samruk-Energy JSC |

35,88 |

6,275 |

35,33 |

6,275 |

39,77 |

7,345 |

|

ERG |

19,23 |

3,387 |

19,16 |

3,387 |

18,87 |

3,387 |

|

CAEPCO JSC |

5,4 |

1,318 |

5,9 |

1,318 |

6,1 |

1,318 |

|

KKS LLP |

6,16 |

1,067 |

6,11 |

1,067 |

6,24 |

1,067 |

|

Enel Group |

227,8 |

84,6 |

207,33 |

81,4 |

191,8 |

80,9 |

|

InterRAO PJSC |

123,0 |

28,0 |

126,7 |

30,8 |

131,6 |

31,2 |

|

RusHydro PJSC |

135,7 |

38,4 |

140,9 |

38,5 |

144,8 |

38,6 |

* The indicators are based on information obtained from publicly available sources.

Greenhouse gas emissions (Scope 1,2)

|

Сompany |

2022 |

2023 |

2024 |

|||

|

Direct GHG emissions, million tCO₂-eq. (Scope 1) |

Indirect GHG emissions, million tCO₂-eq. (Scope 2) |

Direct GHG emissions, million tCO₂-eq. (Scope 1) |

Indirect GHG emissions, million tCO₂-eq. (Scope 2) |

Direct GHG emissions, million tCO₂-eq. (Scope 1 |

Indirect GHG emissions, million tCO₂-eq. (Scope 2) |

|

|

Samruk-Energy JSC |

32,99 |

0,013 |

33,01 |

0,011 |

32,007 |

0,014 |

|

ERG (1) |

29,7 |

0,1 |

29,3 |

0,1 |

29,6 |

0,1 |

|

CAEPCO JSC (3) |

7,6 |

- (2) |

8,1 |

- (2) |

8,5 |

- (2) |

|

KKS LLP |

7,97 |

- (2) |

8,01 |

- (2) |

8,04 |

- (2) |

|

Enel Group (4) |

53,1 |

8,92 |

34,5 |

7,6 |

20,21 |

8,03 |

|

InterRAO PJSC (5) |

73,90 |

- (2) |

75,64 |

- (2) |

78,14 |

- (2) |

|

RusHydro PJSC (4) |

30,88 |

- (2) |

32,05 |

- (2) |

38,49 |

- (2) |

(1) ERG, in addition to power generation assets, owns mining and processing facilities; Scope 1 coverage includes all types of activities performed.

(2)The companies did not disclose information on Scope 2 emissions.

(3) CAEK JSC discloses Scope 1 emissions only for CO₂.

(4) Enel Group and RusHydro PJSC generate energy primarily from renewable energy sources (RES) and hydroelectric power plants, resulting in minimal GHG emissions.

(5) Gas-fired generation plays a significant role in Inter RAO PJSC’s portfolio (over 83%), which is characterized by lower greenhouse gas emissions compared to coal-fired generation.

Freshwater withdrawal, mln m3

|

Company |

2022 |

2023 |

2024 |

|

Samruk-Energy JSC |

208,888 |

228,691 |

220,388 |

|

ERG |

1 989 |

1 947 |

- * |

|

CAEPCO JSC |

31,07 |

30,63 |

26,74 |

|

KKS LLP |

67,92 |

66,95 |

72,19 |

|

Enel Group |

76,0 |

55,0 |

43,4 |

|

InterRAO PJSC |

3 937 |

4 167 |

4 456 |

|

RusHydro PJSC |

686,76 |

708,6 |

695,3 |

* ERG published a condensed version of its 2024 Sustainability Report compared to previous periods, which does not disclose information on the company’s water use.

Specific indicators

|

Сompany |

2022 |

2023 |

2024 |

|||

|

m³ per thous. kWh |

tCO₂-eq. per thous. kWh |

m³ per thous. kWh |

tCO₂-eq. per thous. kWh |

m³ per thous. kWh |

tCO₂-eq. per thous. kWh |

|

|

Samruk-Energy JSC |

5,82 |

0,92 |

6,47 |

0,93 |

5,54 |

0,81 |

|

ERG |

103,43 |

1,55 |

101,62 |

1,53 |

- |

1,57 |

|

CAEPCO JSC |

5,75 |

1,41 |

5,19 |

1,37 |

4,38 |

1,39 |

|

KKS LLP |

11,03 |

1,29 |

10,96 |

1,31 |

11,57 |

1,29 |

|

Enel Group |

0,33 |

0,27 |

0,27 |

0,20 |

0,23 |

0,15 |

|

InterRAO PJSC |

32,01 |

0,60 |

32,89 |

0,60 |

33,86 |

0,59 |

|

RusHydro PJSC |

5,06 |

0,23 |

5,03 |

0,23 |

4,80 |

0,27 |

These companies differ in installed capacity and electricity generation volumes; therefore, the comparative analysis of specific GHG emissions and freshwater consumption indicators is indicative.

Based on the comparative analysis for 2022–2024, Samruk-Energy JSC demonstrates stable and competitive results in carbon and water efficiency compared to peer energy companies.

Greenhouse gas emissions

Samruk-Energy JSC’s specific GHG emissions decreased from 0.93 tCO₂-eq./MWh in 2023 to 0.81 tCO₂-eq./MWh in 2024 (-13%). Regarding this indicator, the Company:

- −remains below ERG (1.53–1.57 tCO₂-eq./MWh), CAEPCO JSC (1.37–1.41) and KKS LLP (1.29–1.31);

- −demonstrates a comparable level with Inter RAO PJSC (0.59–0.60), considering differences in generation structure;

- −is higher than companies with a high share of renewable energy and hydroelectric power — Enel Group (0.15–0.27) and RusHydro PJSC (0.23–0.27).

Water Use

The average specific water consumption of Samruk-Energo JSC for 2022–2024 was 5.94 m³/MWh, which is:

- −17.3 times lower than ERG (~103 m³/MWh);

- −26% higher than RusHydro PJSC (4.96 m³/MWh);

- −21 times higher than Enel Group (0.28 m³/MWh), due to the high share of renewable energy in its generation mix.

Samruk-Energy JSC reaffirms its commitment to sustainable development. The Company continues systematic work to reduce its carbon footprint, implement modern technologies and solutions aimed at lowering GHG emissions. Priorities remain the modernization of main and auxiliary equipment, improvement of resource efficiency, and optimization of water use in subsidiary organizations.

tab2

Air pollutant emissions

We are committed to reducing atmospheric emissions and are implementing measures aimed at minimizing pollutants. Particular attention is given to reducing air pollution at facilities such as ESDPP-1 LLP, SDPP-2 JSC, APP JSC, and Bogatyr Komir LLP, which operate on fossil fuels and have a significant impact on emission levels.

The Company ensures compliance with maximum permissible emission standards, with mandatory reporting to supervisory authorities. Regular air quality monitoring is carried out under the Industrial Environmental Monitoring Program to ensure compliance with environmental standards.

Air emissions are strictly regulated by the environmental legislation of the Republic of Kazakhstan. Emissions of pollutants occur in volumes determined by production processes and in accordance with project documentation and standards approved by authorized government agencies, as stipulated in specific environmental permits.

To minimize air emissions, we regularly assess the performance of equipment and, when necessary, take appropriate measures and implement new technological solutions. At ESDPP-1 LLP, SDPP-2 JSC, APP JSC, and Bogatyr Komir LLP, continuous monitoring is carried out as part of production control over technical and technological parameters that affect emissions, discharges, and waste.

The main sources of air pollutant emissions within the Company include boiler units, oil facilities, fuel oil systems, ash disposal sites, and other pollutant emission sources located at power plants and boiler houses (ESDPP-1 LLP, SDPP-2 JSC, APP JSC, Bogatyr Komir LLP). The primary pollutants generated by these enterprises as a result of fuel combustion and coal mining include nitrogen oxides, sulfur dioxide, particulate matter, carbon monoxide, volatile organic compounds, and other gaseous substance

In 2024, atmospheric pollutant emissions across the Samruk-Energy JSC Group of Companies did not exceed the established maximum permissible limits and amounted to 345,373 tons, compared to the approved limit of 420,010 tons.

Trend in specific air pollutant emissions per unit of output, g/kWh

|

2022 |

2023 |

2024 |

Δ 2024/2023, % |

|

9,5 |

9,5 |

8,2 |

-13,8 |

According to 2024 data, specific air pollutant emissions decreased by 13.8% compared to the 2023 level.

This positive trend is attributed to:

● a reduction in unit consumption of conventional fuel (UCCF) at SDPP-2 JSC from 381.3 g/kWh to 374.7 g/kWh;

● a 2.6-fold increase in electricity generation from renewable energy sources, from 2.849 bn. kWh to 7.460 bn. kWh, resulting from the contribution of assets of Ust-Kamenogorsk HPP LLP and Shulbinsk HPP LLP to the Company’s charter capital.

Air pollutant emissions, tons

|

Pollutants |

2023 |

2024 |

|

NOx (Nitrogen oxides) |

77 745,6 |

75 446,9 |

|

SOx (Sulfur oxides) |

221 132,5 |

214 202,6 |

|

Particulate matter (PM) |

49 234,9 |

49 109,2 |

|

CO (Carbon monoxide) |

6 520,5 |

6 426,5 |

|

Volatile organic compounds (VOCs) |

274,5 |

168,6 |

|

Other gaseous substances |

14,2 |

19,3 |

|

Persistent organic pollutants (POPs) |

0 |

0 |

|

Total |

354 922,3 |

345 373 |

Plans for 2025 and the medium-term outlook

- 1)Study of advanced flue gas cleaning technologies at EGRES-1 LLP, SDPP-2 JSC, and APP JSC, with a focus on the removal of ash, dust, nitrogen oxides (NOx), and sulfur oxides (SOx).

- 2)Determination of final costs for the implementation of Best Available Techniques (BAT) following a comprehensive analysis of available technological solutions.

- 3)Construction of a return pumping station for clarified water as part of the design and estimate documentation (Stage «P») for the project «Expansion and Modernization of Ekibastuz SDPP-2 with Installation of Power Units No. 3 and 4».

tab3

Responsible water use

Samruk-Energy JSC is actively working to identify and prevent potential impacts of its operations on water resources. The Company exercises strict control over the abstraction and use of water at its production facilities to ensure compliance with environmental regulations.

Although our subsidiaries — including ESDPP-1 LLP, SDPP-2 JSC, APP JSC, Bogatyr Komir LLP, Moynak HPP JSC, Shardara HPP JSC, Shulbinsk HPP LLP, Ust-Kamenogorsk HPP LLP, and AZhC JSC — do not operate in water-stressed regions, we place particular emphasis on sustainable water management. Our approach includes assessing water-related risks, implementing strategies to minimize freshwater consumption, and ensuring efficient treatment of wastewater to guarantee its safe return to the natural environment.

Water resource management within the Company complies with the Water Code of the Republic of Kazakhstan and all applicable permits, ensuring the proper protection of water resources.

Key principles of our water resource management approach include:

● Responsible water use and maintenance of a sustainable water balance;

● Identification and accounting of all water intake points, including those involving intermediaries;

● Continuous improvement of strategies to optimize water use;

● Minimization of potable water use for industrial purposes;

● Annual inspection of water intake and discharge metering devices to verify their presence, operability, and timely calibration and sealing by regulatory authorities;

● Avoidance of operations in water-scarce regions, underscoring our environmental responsibility.

The Company’s main water sources include:

– Bestyubinsk Reservoir (Moynak HPP),

– Shardara Reservoir (Shardara HPP),

– Shulbinsk Reservoir (Shulbinsk HPP),

– Ust-Kamenogorsk Reservoir (Ust-Kamenogorsk HPP),

– Satpayev Canal (ESDPP-1 LLP, SDPP-2 JSC),

– Shiderty Canal (SDPP-2 JSC),

– Big Almaty Lake and Bolshaya Almatinka River basin (Hydropower Cascade),

– Kapshagay Reservoir (Kapshagay HPP).

In 2024, the volume of water withdrawn by Samruk-Energy’s subsidiaries for production and household-drinking needs amounted to 80,188,759 megaliters. Of this volume, 99% was used for electricity generation, specifically for the steam-water cycle at thermal power plants (SDPPs and CHPs) and for driving hydro turbines at hydropower plants (HPPs).

Trends in freshwater use for electricity generation, megaliters

|

Indicator |

2022 |

2023 |

2024 |

|

SDPP, CHP |

211 247 |

230 694 |

222 398 |

|

HPP |

63 309 576,63 |

63 455 464,8 |

79 966 361 |

The total water consumption in 2024 amounted to 145,368 megaliters.

As part of our water conservation strategy, we actively utilized closed-loop water supply systems, including cooling reservoirs and once-through ash removal systems at the Ekibastuz thermal power plants. At the Almaty CHP plants, recirculating cooling systems with cooling towers were used, along with water from ash disposal sites, which contributed to improved water use efficiency and environmental protection.

Volume of reused and recirculated water, megaliters

|

Indicator |

2022 |

2023 |

2024 |

|

Volume of reused water |

7 327 |

8 328 |

8 620 |

|

Volume of recirculated water |

3 527 190 |

3 490 881 |

3 541 091 |

Wastewater management

We adhere to high standards for wastewater handling to minimize its negative impact on aquatic ecosystems. Samruk-Energy JSC is committed to staying within established discharge limits and complying with regulatory requirements, which helps protect biodiversity and natural habitats.

In 2024, the Company discharged a total of 80,043,391 megaliters of wastewater.

The Group’s production and operational activities generate two main categories of wastewater:

● More than 99% of the total volume consists of wastewater from ash hydraulic removal systems, water used for cooling technical units at CHPs, and water used in electricity generation at HPPs.

● Less than 1% comprises domestic wastewater from administrative buildings, canteens, and service facilities.

Wastewater is treated using modern physical-chemical and biological technologies. Discharge limits are set based on the methodology approved by the Ministry of Ecology, Geology, and Natural Resources of the Republic of Kazakhstan in March 2021. The quality of treated wastewater is monitored by a certified laboratory to ensure compliance with environmental standards.

Surface water quality is assessed using both general and specific indicators. General indicators include mineralization, pH, hardness, and others. Specific indicators include chemical and biochemical oxygen demand, concentrations of petroleum products, ammonium salts, nitrates, phosphates, and other pollutants.

In 2024, no cases of exceeding the maximum allowable concentrations of pollutants in domestic wastewater discharges were recorded.

tab3333

Waste management

Responsible waste management is a key component of Samruk-Energy JSC’s environmental strategy. We are committed to efficient resource use and minimizing the environmental impact of waste across all stages of our operations — from electricity generation to asset operation.

The Company conducts its waste management activities in full compliance with the legislation of the Republic of Kazakhstan. This includes tracking the quantities of waste generated, treated, recycled, disposed of, transferred to or received from third parties, and stored. Data are compiled quarterly and annually.

Waste management is implemented in strict accordance with established standards and procedures, including:

● The Corporate Standard on Environmental Management;

● Waste Management Programs;

● The Waste Management Action Plan.

In line with the classification criteria established by the authorized environmental agency, all waste is categorized as either hazardous or non-hazardous.

Hazardous waste requires specialized disposal methods, while non-hazardous waste is subject to separate collection and recycling. Designated collection points and areas are equipped with labeled containers and metal bins to facilitate proper segregation. Standards are also in place for identifying waste that may not be landfilled and materials that are suitable for processing into secondary raw materials.

Given the operational specifics of ESDPP-1 LLP, SDPP-2 JSC, and APP JSC, the majority of the Company’s total waste volume consists of high-tonnage non-hazardous waste — specifically, ash and slag waste and overburden from coal mining at Bogatyr Komir LLP.

Bogatyr Komir LLP is actively working to reduce its environmental footprint by minimizing the volume of overburden deposited in external dumps. As part of this initiative, the Company is developing plans to repurpose exhausted areas of the Northern and Bogatyr coal pits for use as internal dumps. In addition, to prevent oxidation and spontaneous combustion of coal-containing rock, inert materials are used for isolation, and surface layers are compacted.

Ash and slag waste generated by ESDPP-1 LLP, SDPP-2 JSC, and APP JSC is stored at ash disposal sites. Dust suppression measures are in place — at the Ekibastuz SDPPs, this includes submerging waste under the waterline, while APP JSC employs a unique combined technology involving soil covering and planting of perennial grasses and shrubs. We conduct annual land reclamation of the used portions of ash disposal sites. In addition to disposal, ash and slag are also recycled for use in road construction and building material production.

The expansion of HPPs and renewable energy facilities within Samruk-Energy JSC contributes to reducing the volume of ash and slag waste per unit of electricity produced.

Hazardous waste includes industrial and operational waste such as batteries, used mercury-containing lamps, waste oils and technical fluids, fuels and lubricants, dyes, resins, varnishes, and paints.

Between 2020 and 2024, 285 kilograms of used batteries were collected and sent for recycling.

During operations, ESDPP-1 LLP, SDPP-2 JSC, APP JSC, and Bogatyr Komir LLP do not generate radioactive waste. Quarterly radiation monitoring is carried out, and results consistently show radiation levels remain within the safe standard of 2.5 µSv/h, confirming the effectiveness of existing radiation safety measures.

Samruk-Energy JSC also monitors the performance of contractors involved in waste management. During procurement procedures, bidders are required to present valid licenses for handling each type of waste, as well as evidence of sufficient infrastructure and equipment. Contractors sign agreements obligating them to comply with the environmental laws of the Republic of Kazakhstan.

Samruk-Energy JSC maintains ongoing dialogue with stakeholders. Any individual can express concerns related to the environmental aspects of our operations through designated feedback channels. All submissions are officially logged and reviewed.

Total waste volume generated by Samruk-Energy JSC enterprises, tons

|

Indicator |

2022 |

2023 |

2024 |

|

Total waste generated, including: |

89 929 927 |

98 496 096 |

108 784 900 |

|

– hazardous waste |

647 |

1 732 |

534 |

|

– non-hazardous waste |

89 928 281 |

98 496 364 |

108 784 366 |

|

of which, by key waste types specific to production activities: |

89 912 725 |

98 474 212 |

108 760 267 |

|

– ash and slag waste |

7 129 158 |

8 853 230 |

8 781 174 |

|

– overburden |

82 783 567 |

89 620 982 |

99 979 093 |

tab4444

Biodiversity conservation

Samruk-Energy JSC fully recognizes its responsibility for the conservation of biodiversity. We are committed not only to achieving “no net loss”, but also striving for a “net positive impact” on biodiversity across all our operations. This applies to the construction of new facilities, modernization and operation of existing assets, as well as their decommissioning.

Key areas of focus for preserving and protecting biodiversity include:

- ●Deployment of advanced technologies that reduce environmental impact during production.

- ●Development and implementation of biodiversity protection and conservation programs in areas adjacent to production sites.

- ●Regular environmental monitoring to identify and address ecosystem threats in a timely manner.

In accordance with the environmental legislation of the Republic of Kazakhstan, any expansion or modernization of production activities is preceded by an assessment of potential impacts on the ecological system and the biodiversity of the region where our facilities are located. To ensure public participation in decision-making, public hearings are held with open access to all project documentation.

Across all aspects of our operations—from power generation to decommissioning—we actively work to protect and enhance the condition of natural ecosystems.

This work includes wildlife conservation projects, collaboration with research institutions and scientific organizations, as well as engagement with government authorities. A notable example of cooperation with international environmental organizations is the project implemented by Moynak HPP JSC in partnership with UNDP Kazakhstan, aimed at preserving the relict ash forest along the Charyn River.

In 2024, the activities of our subsidiaries did not have any significant direct or indirect impact on vulnerable ecosystems or biodiversity.

In 2024, KZT 224,100 was invested in landscaping and greening of the sanitary protection zones of the Company’s subsidiaries, which represents a 95.4% increase compared to the previous year.

Investments in biodiversity conservation, million KZT

|

2022 |

2023 |

2024 |

|

57,9 |

114,7 |

224,1 |

Biodiversity conservation initiatives:

- ●To minimize fish mortality, hydro turbines at our hydropower plants are equipped with fish protection devices. Additionally, as a preventive measure, searchlights are used near the water intake in front of turbine pipelines during nighttime hours to deter fish from approaching.

- ●To reduce bird fatalities caused by using overhead power line towers as perching sites, AZhC JSC is implementing projects to retrofit poles with insulated wires and install special bird deterrent devices to prevent birds from landing on crossarms.

- ●At the pre-design and design stages of wind power plants (WPPs), measures are taken to reduce their environmental impact. In particular, to mitigate light pollution that can disrupt the natural biorhythms of living organisms and to preserve and restore biodiversity, lighting at WPPs is kept to a minimum, limited to mandatory obstruction lights only.

- ●Greening of industrial areas and expansion of green space coverage.

- ●As part of the industrial environmental monitoring program, regular laboratory testing is planned to monitor and assess the environmental impact of the Company’s operations.

- ●Reclamation of decommissioned ash disposal sites is being designed. These efforts aim to restore and convert the sites into environmentally safe and functional areas.

Restoration of Fish Populations in the Irtysh River

The Ust-Kamenogorsk and Shulbinsk hydropower plants continue to contribute to maintaining the region’s ecological balance by regularly implementing fish stocking programs. In 2024, as part of an environmental initiative, 130,111 juvenile carp were released into the Irtysh River. The release location was carefully selected in coordination with a scientific organization, which identified the optimal site — the village of Azovoye, located along the Irtysh River. This area was chosen due to its favorable natural conditions for the survival and reproduction of juvenile fish, helping to strengthen the population of this species.

Such initiatives have a positive impact on maintaining the fish population in the reservoir and contribute to preserving the region’s ecosystem as a whole.

We place particular emphasis on the development and implementation of measures aimed at minimizing the environmental impact of our operations. This includes not only restoring the ecological value of reclaimed land but also supporting biodiversity and protecting unique ecosystems.

In accordance with the Environmental Code, we are legally obligated to decommission ash disposal sites, which are designated areas for the storage of operational waste.

In 2024, the estimated decommissioning fund for ash disposal sites amounted to KZT 3,739.3 million, representing an 18.96% increase compared to the previous year. This growth is primarily due to higher costs of reclamation works and materials.

Carrying amount of the ash dump decommissioning reserve, million KZT

|

2023 |

2024 |

Δ 2024/2023, % |

|

3 143,4 |

3 739,3 |

18,96 |

In the regions where it operates, Samruk-Energy is committed to active and inclusive cooperation with local communities, regional authorities, public organizations, and other stakeholders from the early stages of facility decommissioning. The Company employs a variety of engagement formats, including thematic conferences, one-on-one meetings, press briefings, phone consultations, public hearings, as well as perception surveys and stakeholder research.

tab1111

As part of its climate agenda, Samruk-Energy JSC seeks to contribute to achieving Kazakhstan’s national carbon-neutrality targets by 2060. In this context, the Company has developed the Samruk-Energy Energy transition Program through 2060.

The Company’s energy transition is primarily driven by global climate-action trends, including the following:

- The Paris Climate Agreement adopted in December 2015, which encourages governments worldwide to reduce greenhouse-gas emissions and help limit the increase in global average temperature to well below 2°C.

- The introduction of international carbon-regulation mechanisms, including the EU’s Carbon Border Adjustment Mechanism (CBAM) under the European Green Deal.

- Commitment to the United Nations’ 17 Sustainable Development Goals, including those focused on climate action and environmental protection.

- Stricter requirements introduced under Kazakhstan’s Environmental Code as of July 1, 2021, which strengthened greenhouse-gas emission regulations and launched the national emissions-trading system.

- Kazakhstan’s endorsement of the Global Methane Pledge (announced by the Head of State at the COP28 World Climate Summit in Dubai in December 2023).

tab1112

Goals and directions of the Energy transition Program

The Company sets targets and develops a long-term vision for low-carbon development by increasing the share of renewable energy and hydropower in its generation mix, adopting low-carbon technologies (including CCUS and clean-coal technologies), enhancing energy efficiency, applying offset mechanisms, and other measures.

Given the significance of global climate-mitigation trends and the risks associated with conventional generation, Samruk-Energy JSC will seek to minimize its negative environmental impact through 2060 while adhering to its Strategic Mission:

“We ensure the country’s energy security and contribute to an accelerated energy transition by following the principles of sustainable development and effective resource management”.

The objective of the Program is to reduce the Company’s net carbon footprint by 2060.

Key pillars and tasks of the Energy transition Program:

- Reduction of CO₂ emissions through the gasification of coal-fired thermal power plants.

- Modernization of power grids and implementation of Smart Grid

- Development of energy storage systems and flexible generation

- Implementation of coal enrichment and gasification technologies

- Implementation of carbon capture, utilization, and storage (CCUS) systems

- Improvement of energy efficiency and resource conservation

- Development of “green” transport

- Creation of carbon farms and implementation of offset projects

- Development of carbon accounting and a digital monitoring system

- Improvement of Kazakhstan’s regulatory framework

- Attraction of “green” financing

- Ensuring compliance with ESG criteria

- Localization of production

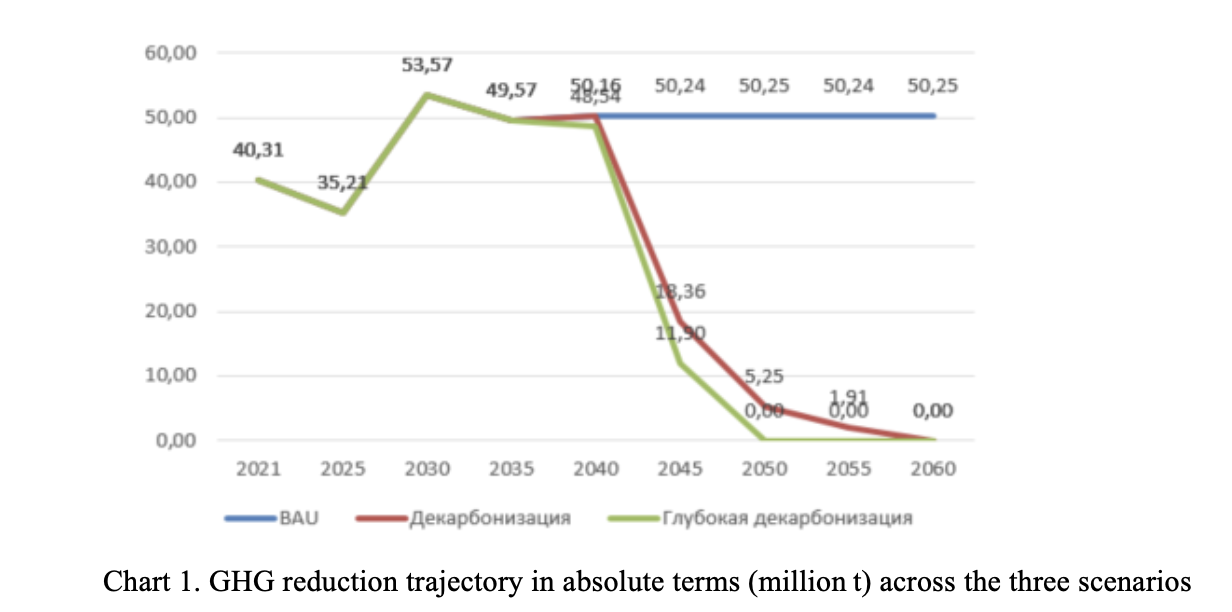

As part of the current Program and selected focus areas, the Company is exploring three potential development scenarios:

1) Business as Usual (BAU) – the baseline scenario models the Company’s development in the absence of significant technological breakthroughs and new climate policies.

2) Decarbonization – a moderate decarbonization scenario, assuming a gradual reduction of the carbon footprint. It is the unconditional target scenario and represents the optimal development pathway.

3) Deep decarbonization – an ambitious plan aimed at achieving carbon neutrality in the shortest possible time. It is a conditional target scenario and may be implemented under additional conditions.

The chart presents the aggregated dynamics of GHG reductions under the three scenarios.

The Company has adopted a deep decarbonization scenario, targeting carbon neutrality by 2050.

For further details, please refer to the attached materials.

tab1113

The Company prioritizes climate risk management to provide a reasonable assurance of achieving its strategic objectives. Samruk-Energy JSC implements a comprehensive set of measures to manage climate risks. Climate risk assessments are integrated into the development of the Company’s strategy, the evaluation of investment projects, and the preparation of annual and medium-term plans.

As part of the analysis of the Program’s development scenarios, the Company has identified the key climate-related physical and transition risks.

Further information is available in the attached materials.

tab4446

1. Introduction

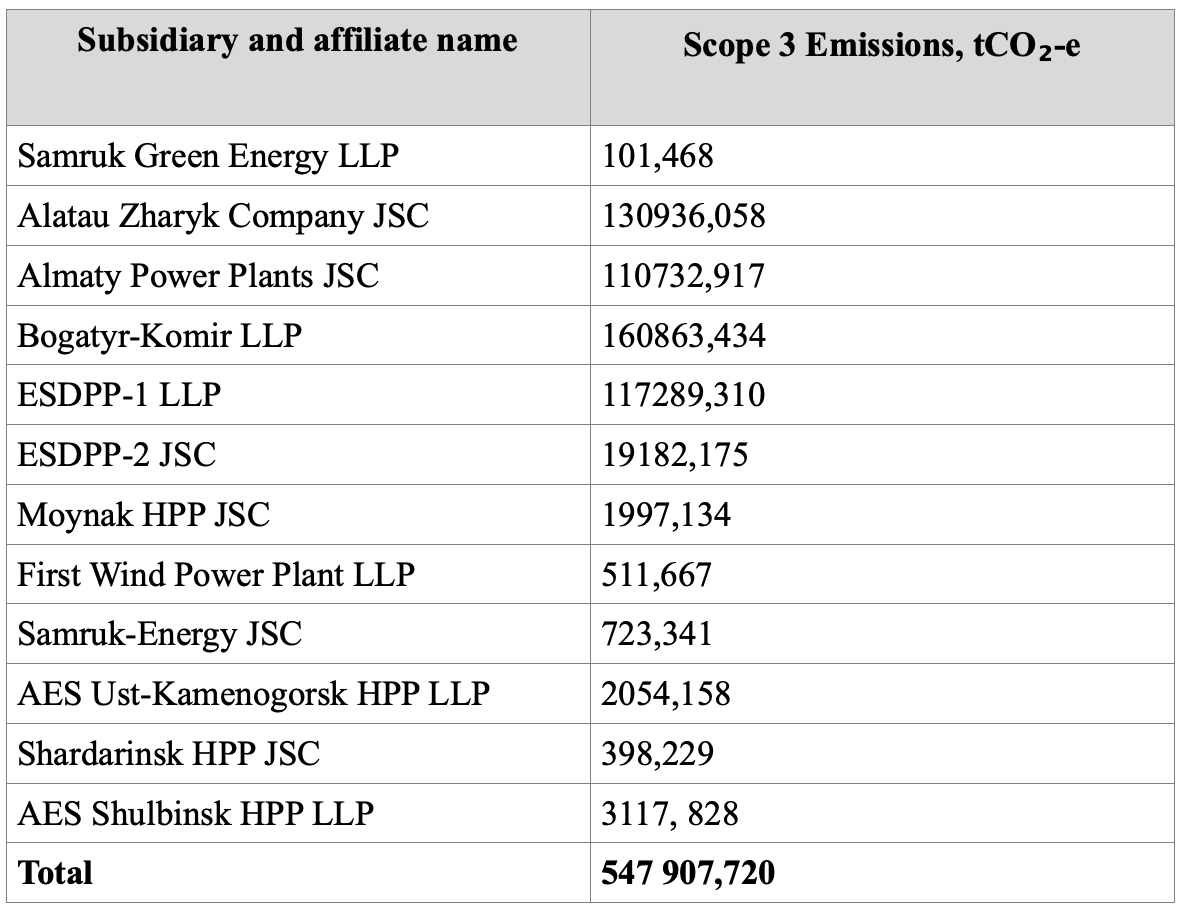

To enhance the transparency, accuracy, and completeness of corporate greenhouse gas (GHG) reporting, in 2025 Samruk-Energy group expanded the coverage of Scope 3 emissions accounting and conducted a comprehensive inventory of indirect emissions associated with the value chain.

This work is aimed at improving the Group’s carbon footprint management system, identifying emission reduction opportunities, and strengthening alignment with international sustainability standards.

2. Methodological framework

The calculations were performed in accordance with internationally recognized standards and national regulatory requirements, including:

• GHG Protocol: Technical Guidance for Calculating Scope 3 Emissions (WRI and WBCSD).

• Order No. 260 dated 19.07. 2021 issued by the acting Minister of Ecology, Geology and Natural Resources of the RK approving the list of benchmarks for regulated sectors of the economy.

• Order No. 9 dated 17.01. 2023 issued by the Minister of Ecology and Natural Resources of the RK, including:

o Appendix 2 — methodology for calculating GHG emissions from boilers of TPPs, CHPs and boiler houses;

o Appendix 8 — methodology for calculating GHG emissions from coal mining.

• IPCC 2006 Guidelines for National Greenhouse Gas Inventories — Volume 2, Chapter 4 “Fugitive Emissions”.

• International electronic emission factor databases, including:

o https://www.climatiq.io

o https://www.epa.gov/climateleadership/ghg-emission-factors-hub

The applied methodologies ensure data comparability, calculation transparency, and accurate accounting for all relevant Scope 3 emission categories.

3. System boundaries and applicability of Scope 3 categories

Scope 3 includes indirect emissions that occur outside the organization’s direct operational control but arise as a consequence of its activities. System boundaries are defined by the full life cycle of products and services — from raw material extraction and production to transportation, use, and end-of-life treatment.

The inventory covered emissions from the following subsidiaries and affiliates of the Group:

• “Ekibastuz GRES-1 named after Bulat Nurzhanov” LLP

• “Station Ekibastuzskaya GRES-2” JSC

• JSC “Almaty electric stations”

• AZhC JSC

• Bogatyr Komir LLP

• Moynak HPP JSC

• Shardarinsk HPP JSC

• AES Ust-Kamenogorsk HPP LLP

• AES Shulbinsk HPP LLP

• FWPP LLP

• Samruk Green Energy LLP

• Head Office of Samruk-Energy JSC

4. Scope 3 Emission categories included in the 2024 calculations

The assessment of indirect emissions was carried out across all relevant categories in accordance with the GHG Protocol. The following categories were included in the calculations:

- Purchased goods and services

- Capital goods (equipment)

- Fuel- and energy-related activities not included in Scope 2 (applicable to Bogatyr Komir LLP and AZhС JSC)

- Upstream transportation and distribution of purchased goods

- Waste generated in operations

- Business travel

- Employee commuting (to/from place of work)

- Upstream transportation and distribution of sold products — applicable to Bogatyr Komir LLP

- Use of sold products — applicable to Bogatyr Komir LLP

- Category 13 — leased assets (downstream), applicable to the Head Office of Samruk-Energy JSC

Categories identified as insignificant or not applicable

Based on the analysis, the following categories were determined to be not relevant:

• Category 8 — leased assets (upstream)

• Category 10 — processing of sold products

• Category 12 — end-of-life treatment of sold products

• Category 14 — franchises

• Category 15 — investments

The non-applicability is driven by the nature of production processes, the absence of any processing of sold products (electricity and coal), minimal use of leased assets, and the absence of franchising or investment activities among SA.

5. Gases used and emission structure

The calculations were performed in accordance with the requirements of the GHG Protocol and national methodologies, covering the following greenhouse gases:

• CO₂ (carbon dioxide)

• CH₄ (methane)

• N₂O (nitrous oxide)

All emissions are expressed in CO₂-equivalents.

6. Results and coverage of calculations

The conducted Scope 3 indirect emissions inventory enabled to:

• compile a comprehensive list of significant sources of indirect emissions across subsidiaries and affiliates;

• quantitatively assess gross emissions for each applicable Scope 3 category;

• expand the corporate carbon footprint database;

• ensure comparability of reporting with international ESG standards.

7. Results of quantitative assessment of Scope 3 emissions

The results of the gross Scope 3 emissions calculations across all subsidiaries and affiliates of the Group are presented in the table below.

Based on the conducted inventory, the total gross Scope 3 greenhouse gas emissions of the Samruk-Energy group for 2024 amounted to 547,907.720 tCO₂-e.

This figure reflects the extent of the Group’s indirect impact on emissions across the entire value chain and forms the basis for subsequent management decisions aimed at reducing the carbon footprint and achieving the Group’s corporate ESG objectives.

8. Analysis of major Scope 3 emission sources across SA

As part of the 2024 Scope 3 emissions assessment, an analysis of category-level contributions for subsidiaries and affiliates was conducted. Key findings by enterprise are presented below.

Alatau Zharyk Company JSC

The main contributor to the enterprise’s total Scope 3 emissions was Category 3 — Other indirect emissions from energy consumption.

Alatau Zharyk Company JSC is an electricity distributor, and therefore the majority of emissions are associated with the life cycle of fuel used for the generation of consumed electricity and grid losses.

Ekibastuz SDPP-1 LLP

For Ekibastuz SDPP-1 LLP, the key contributor to Scope 3 emissions in 2024 was Category 5 — Waste generated in operations. During the reporting year, the enterprise disposed of a significant volume of waste, leading to an increase in emissions in this category. These emissions primarily resulted from the transportation, processing, and disposal of waste, including residual fuels, materials, and production waste.

Almaty Power Plants JSC

For Almaty Power Plants JSC, the main Scope 3 emission sources were Category 4 (Upstream transportation and distribution of purchased goods) and Category 5 (Waste generated in operations).

Coal is the primary fuel for energy generation at the enterprise, which leads to:

• Significant emissions associated with transporting fuel from mining sites to the plant;

• Emissions resulting from the disposal of coal combustion residues, including ash and slag materials, as well as associated production residues.

Bogatyr Komir LLP

Within Bogatyr Komir LLP’s Scope 3 emissions profile, the largest contributions came from Category 3 (other indirect emissions from energy consumption) and Category 11 (use of sold products).

• The enterprise is a major electricity consumer, generating significant emissions related to the life cycle of fuel used for electricity generation.

• Simultaneously, Bogatyr Komir LLP is one of the largest coal mining companies in the region.

As a result, a substantial share of Scope 3 emissions arises from Category 11 — Use of sold products, i.e., emissions occurring when the sold coal is fired by end-users.

tab4

Сollaboration

“Samruk-Energy” JSC pays special attention to new technologies:

By the order of “Samruk-Energy” JSC, a scientific laboratory “Clean Coal Technologies” was established at the premises of Nazarbayev University IEO;

Participation in national and international projects / initiatives / associations

1) The company is a member of the ALE "Kazakhstan Electricity Association".

2) The company is a member of the ALE "Kazakhstan Association of Oil Gas And Energy Sector Organizations “Kazenergy"

tab

Occupational Safety and Health

Thank you for visiting our website. Your feedback is valuable to us, and we will certainly take it into account in our work. Feel free to share your suggestions through the "Comments and Suggestions" section. We look forward to collaborating with you!

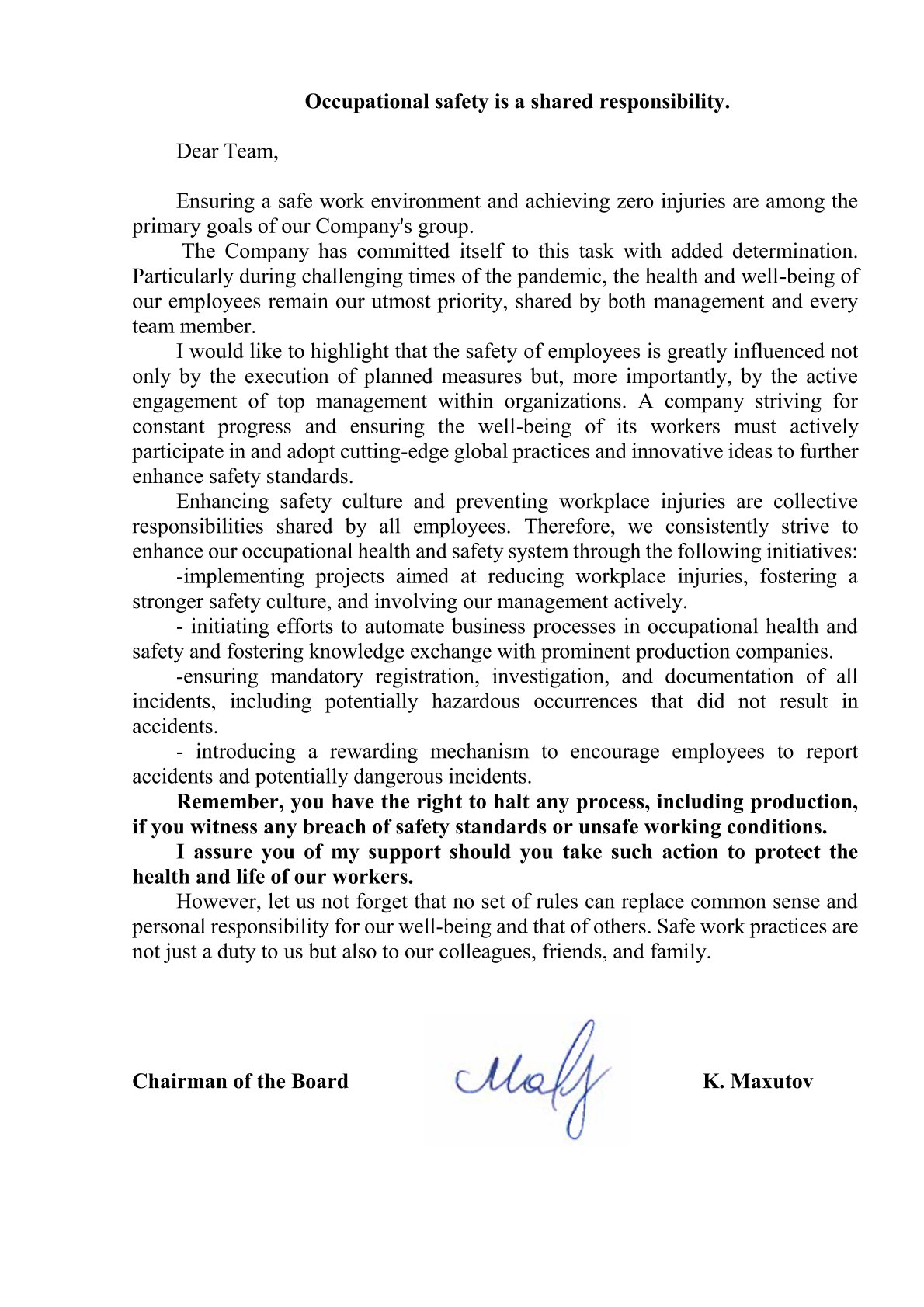

Address from the Chairman of the Board of “Samruk-Energy” JSC:

tab

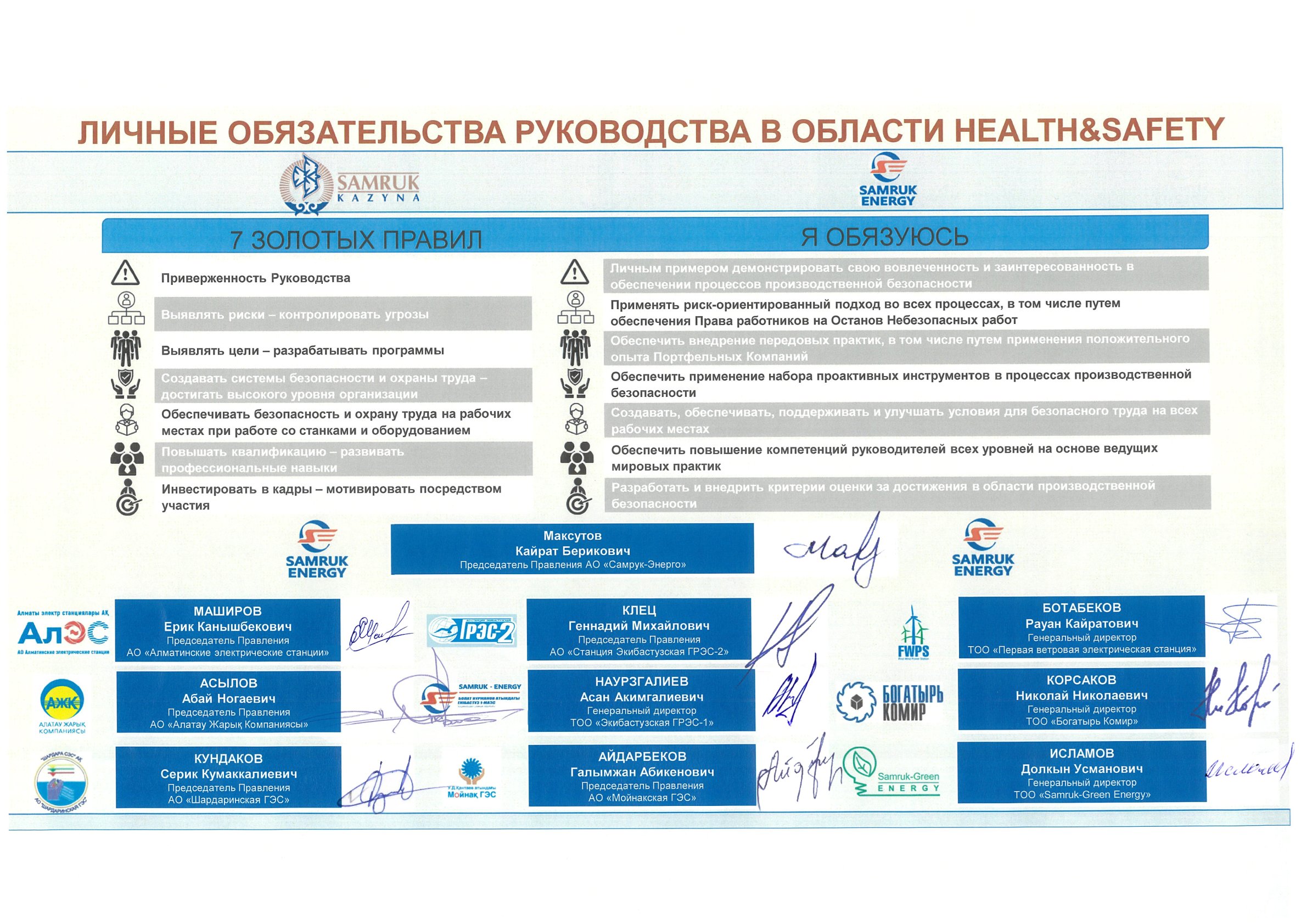

Signed commitments related to occupational health and safety of the Chairman of the Board of "Samruk-Energy" JSC and chief executive officers of SA

tab5

Our approach

To enhance the efficiency of occupational health and safety management system, the Company has developed and adopted internal corporate standards:

- occupational health and safety policy;

- rules for providing information in case of accidents;

- subsidiaries and affiliates of “Samruk-Energy” JSC are certified according to ISO 45001 requirements.

“Samruk-Energy” JSC aims to lead in health protection and workplace safety.

The Company's management recognizes that its most valuable resource is its workforce. Effectively implementing policies regarding occupational health and safety, which includes improving working conditions, implementing advanced technologies, and providing comprehensive employee training, is crucial for the success of both the Company and the well-being of our Republic.

The Company commits to comply with the requirements of the Republic of Kazakhstan law in occupational health and safety, as well as international standards for occupational health and safety.

tab6

Ongoing projects

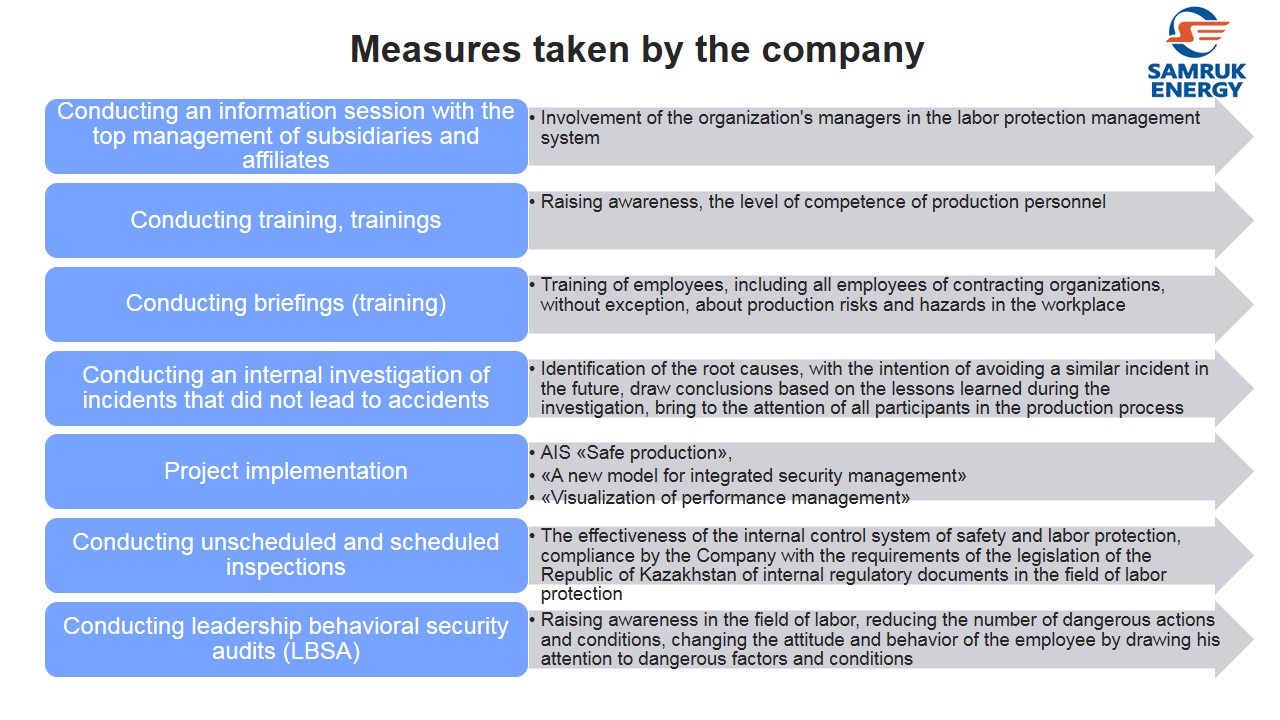

Project "Implementation of a new model for integrated security management"

Goal:

- Improvement of the occupational safety management system based on a conscious attitude to the culture of safe work, commitment, leadership and responsibility of managers and employees for safety, with a subsequent reduction in the level of injuries.

Benefits:

- Improving the safety culture/Involvement of personnel in occupational safety issues; Number of reports/appeals (about potentially dangerous incidents, about dangerous/safe behavior);

- Reduction of injury rates (LTIFR);

- Improving the evaluation of the effectiveness of the occupational health and safety management system;

The project "Safe production"

Goal:

- Reducing the level of occupational injuries by increasing the level of safety culture of employees, through the introduction of an accessible and transparent automated system for registration and investigation of incidents

Benefits:

- Registration and investigation of inconsistencies, formation of a corrective action plan. Registration of internal inspections on safety and labor protection.

- Registration of Leadership behavioral security audit, control of training, certification and training of personnel.

- Automation of business processes in the field of occupational safety and health.

The project "Visualization of efficiency and awareness management"

Goal:

- Raising awareness of senior managers on occupational safety and health issues

Benefits:

- Involvement of the first heads of subsidiaries on safety and labor protection issues;

- Improving the efficiency of the management of the occupational safety and health system;

tab7

The Company’s activities in workplace health and safety

Occupational health and safety is a course of action to ensure the safety of the vital signs of workers during the production process, consisting of a variety of regulatory, legal, socio-economic, sanitary, medical, preventive, rehabilitation and other measures and requirements.

Safety precautions are a series of measures taken by the employer aimed at creating a safe environment in the process of the employee performing his job duties.

The top management of the Company is aware that in order to increase the effectiveness of the implementation of goals and objectives, it is necessary to increase the level of involvement of executives of subsidiaries and affiliates by demonstrating personal commitment to occupational health and safety issues.

Ongoing activities:

control of the provision of employees of enterprises with means of individual and collective protection;

providing methodological and informational assistance to subsidiaries and affiliates on safety and occupational health issues;

monitoring the system of transparent registration of industrial accidents;

monitoring of the system of individual responsibility (security coupons);

identifying hazards and evaluating risk significance;

work safety analysis;

mechanisms have been developed to reward employees for reporting potentially hazardous incidents;

participation in internal investigations of accidents to identify root (systemic) causes;

registration and investigation of potentially dangerous incidents to prevent accidents;

conducting seminar-meetings on occupational health and safety at production facilities, involving specialists from OHS departments in subsidiaries and affiliates of the Company;

supervising the training of top managers and occupational safety specialists in IOSH and NEBOSH courses;

automated system for registering occupational health and safety related incidents and violations;

initiating a Memorandum of Cooperation in occupational health and safety with leading companies;

competition in occupational health and safety across the group of companies;

tab8

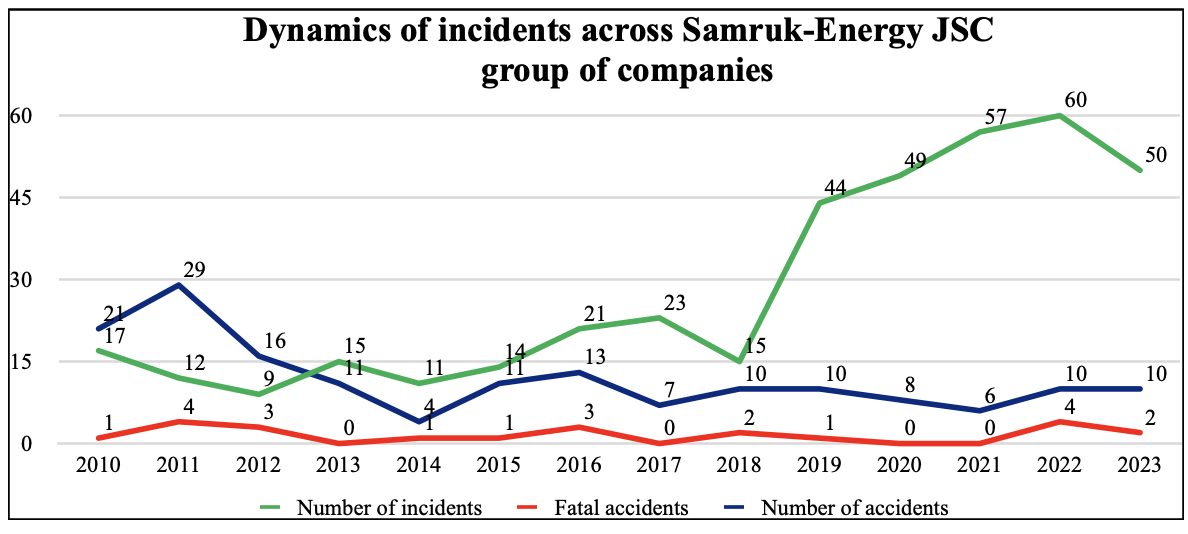

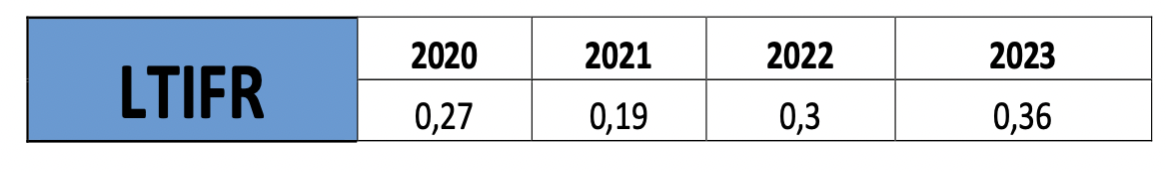

Workplace injury rate statistics

The Company takes all necessary actions on implementing the tasks set, whilst implementing the best world practices. The implementation of the above projects currently shows intermediate results in terms of accidents / registered workplace accidentsInjury statistics for the period from 2010 to the 1st half of 2023 are shown in a graphical representation

Types of accidents and root causes of industrial accidents:

- Insufficient identification of hazards and risk assessment.

- Victim's fall

- Impact of moving, flying, rotating objects and parts

- Personal negligence of the victim

- Unsatisfactory organization of work

- Improper control of line personnel

- Violation of safety and labor protection rules

tab

Video analytics

New technologies have already been successfully implemented to enhance workplace safety, specifically using artificial intelligence to detect and prevent violations and incidents. The following projects have been tested and deployed: Workplace video analytics, driver video analytics, and smart helmets with cameras. These technologies have been applied in five subsidiaries: AZhC, Almaty Power Plants (AlES), Bogatyr Komir, Shulbinsk HPP, and Ust-Kamenogorsk HPP. Specifically:

- AlES has installed 1,200 fixed cameras across all workplaces to monitor unsafe actions, non-use of personal protective equipment (PPE), and improper clothing in real time. The system can not only identify the type of violation but also use Face ID to recognize the employee responsible and send notifications to both the supervisor’s computer and the employee’s mobile phone. On a monthly basis, 1,065 violations are detected. Additional 400 cameras will be installed in 2025.

- Bogatyr Komir launched the Antison driver video analytics system on June 23, 2025, installed on all 60 dump trucks. This system accurately detects dangerous driver behaviors, including drowsiness, smoking, route deviations, and phone use. When a violation is detected, a vibration motor in the driver’s seat is activated, an audible alarm sounds in the cab, and a signal with video and photo evidence is sent to the control center. Since July 1, 2025, 1,392 violations have been recorded, reducing the likelihood of accidents and incidents in transportation.

- AZhC successfully implemented the “Smart helmets” system in January 2025, consisting of helmets equipped with cameras and artificial intelligence. 31 units have been deployed, with 100 more planned for 2025. These helmets detect non-use of PPE, absence of protective clothing, and entry into hazardous areas, and they allow remote real-time feedback via a microphone. On average, 3–4 violations are detected monthly.

- Shulbinsk and Ust-Kamenogorsk HPPs introduced the Driver Assistance System on March 4, 2025, using 360-degree dashcams installed on nine vehicles (six more vehicles planned). The system monitors speeding, drowsiness, route deviations, lane departures, smoking, and seatbelt compliance. Since deployment, violations decreased from 12 to 3, a fourfold reduction.

The implementation of these new systems in the management of occupational safety processes has become one of the key elements in ensuring workplace safety, and Samruk is no exception.

The introduction of video-based technologies combined with advanced AI video analytics represents a strategic step that fundamentally changes the approach to occupational safety. This minimizes the likelihood of accidents and incidents, which is essential for protecting the lives and health of employees. The goal is for all employees to return home safe and unharmed.

Antison (anti-sleep system)

Over 1,200 smart cameras have been installed at AlES facilities.

-To enhance industrial safety, AlES implemented a modern AI and video analytics system. Today, the company’s facilities are equipped with over 1,200 IP cameras, smart turnstiles, breathalyzers, and Face ID systems.

What does the new system offer?

- Timely response to threats

- Detection of occupational safety violations (non-use of PPE, unauthorized access to hazardous areas, foreign objects)

- Employee movement monitoring and process transparency

- During 2025–2026, drones and signaling systems will be integrated into the safety infrastructure at AlES facilities

- Our goal – full compliance with occupational safety regulations and zero workplace injuries.

tab10

Development of energy conversation and energy efficiency

“Samruk-Energy” JSC is a leading producer of electricity, which plays a vital role in the country's energy system.

In accordance with the Law of the Republic of Kazakhstan "On Energy Saving and Improving Energy Efficiency," energy audits are conducted in all of the Company's subsidiaries and dependent organizations that are subjects of the State Energy Register, with the involvement of specialized accredited organizations.

Creating a sustainable economic development model is impossible without addressing energy efficiency and conservation.

A policy of efficient and rational energy consumption should curb consumption growth and significantly reduce environmental impacts.

2024 has been a year of sustainable growth, strategic decisions, and significant achievements for Samruk-Energy JSC. Energy conservation is a key factor in sustainable development, and we are proud of the results we have already achieved in this area. A total of 67 measures have been implemented to improve energy efficiency and rational use of resources, resulting in savings of over 1.2 billion tenge. These results were made possible through teamwork, new technologies, and continuous efficiency monitoring. We don't intend to rest on our laurels and are already working on new initiatives to make our energy consumption even more responsible.

Plans for 2025 and the Medium Term

- The Energy Conservation and Energy Efficiency Program is planned to be updated, taking into account modern challenges and sustainable development priorities, in the following key areas:

- Optimization of the use of electricity, heat, coal, and other resources.

- Increasing the energy efficiency of equipment, engineering systems, and production processes.

- Reducing energy costs.

- Increasing the economic efficiency of production activities.

- Reducing greenhouse gas emissions.

- Minimizing the negative impact on the environment.

- Introduction of modern energy-efficient technologies and equipment.

- Transition to energy-efficient solutions (LED lighting, automated control systems, etc.).

- Raising awareness and training staff and the public.

- Promoting responsible and rational resource consumption.

- Strengthening resilience to potential energy crises and external risks.

- The implementation of 65 measures aimed at energy conservation and energy efficiency is planned, with an expected economic impact of over 1 billion tenge.

tab11

Our approach

“Samruk-Energy” JSC group of companies places a strong emphasis on effective engagement with stakeholders, recognizing its paramount importance. Guided by principles of transparency and social responsibility, the group ensures sustainable development where the Company, its stakeholders, and society can collectively learn, assess, and analyze the needs, expectations, and opinions of both internal and external stakeholders; challenges and opportunities from the perspective of stakeholders; the most significant issues of concern to internal and external stakeholders.

The approach to responsible, thoughtful, and rational stakeholder interaction, grounded in standards like the AA1000 series, GRI, and other best practices, aids in making informed decisions about the Company's strategic development and methods to enhance its operations.

“Samruk-Energy” JSC's engagement with stakeholders is characterized by its commitment to investing in development, the future of its customers, employees, partners, and suppliers, thereby ensuring the sustainable progress of both the Company and local communities. It entails making social investments in areas of significance within the Company's presence territory, alongside a readiness to foster collaboration with all parties for adaptable responses to external and internal challenges.

To enhance the efficiency of stakeholder interaction, “Samruk-Energy” JSC has implemented a Communication Strategy across the entire group of companies. This strategy establishes a unified approach to corporate communications, delineates target audiences, communication principles, media planning, crisis response procedures, internal and external PR tools, and the Company's external positioning. The management of sustainable development within the Company governs the policy and methodology for stakeholder engagement.

The corporate communications policy, stakeholder identification, impact assessment, and the identification of material topics are subject to approval and oversight at the Board of Directors level.

The execution of initiatives and plans for stakeholder interaction, along with their monitoring, falls under the competence of the Company's Management Board. Annually, the Board reports to the directors on the outcomes of activities related to stakeholder engagement.

Specially established Committees under the Board of Directors and the Management Board oversee the stakeholder interaction system within their respective areas of responsibility.

The outcomes derived from the Company's engagement with stakeholders serve as the cornerstone for a robust and validated sustainable development policy. Within this framework, the Company endeavors to extensively incorporate sustainable development principles by adopting best practices in production, environmental initiatives, occupational safety, and the social sphere. This approach aims to foster economic growth in the regions where the Company operates while maintaining an optimal balance between stakeholder interests and the Company's strategic objectives.

Engagement with stakeholders not only helps in cultivating social capital but also aids in the prevention and mitigation of risks while identifying fresh opportunities for advancement.

tab1666

Stakeholder Engagement System Assessment

It is crucial for the Company to ensure that all stakeholders, both external and internal, are heard. The Company insists on its employees and stakeholders adhering to high standards of ethics and integrity, as well as all legal requirements.

All stakeholders may report any actual or suspected theft, fraud, corruption, violations of the Fundamental Business Principles, the Code of Conduct, or violations of the laws of the Republic of Kazakhstan, and may also submit their suggestions in the following ways:

|

|

|

|

|

|

|

Hotline https://www.samruk-energy.kz/en/navigation-and-support/hotline |

Feedback for all stakeholders https://www.samruk-energy.kz/en/navigation-and-support/feedback-all/feedback |

Feedback for temporary workers or individuals not employed by the group of companies and other stakeholders on ongoing projects: https://www.samruk-energy.kz/en/navigation-and-support/feedback-all/feedback-other |

Chairman of the Management Board Blog https://www.samruk-energy.kz/en/navigation-and-support/chairmans-blog |

Ombudsman https://www.samruk-energy.kz/en/company/corporate-governance/corporate-governance-main-en/ombudsman |

Annual Report Questionnaire |

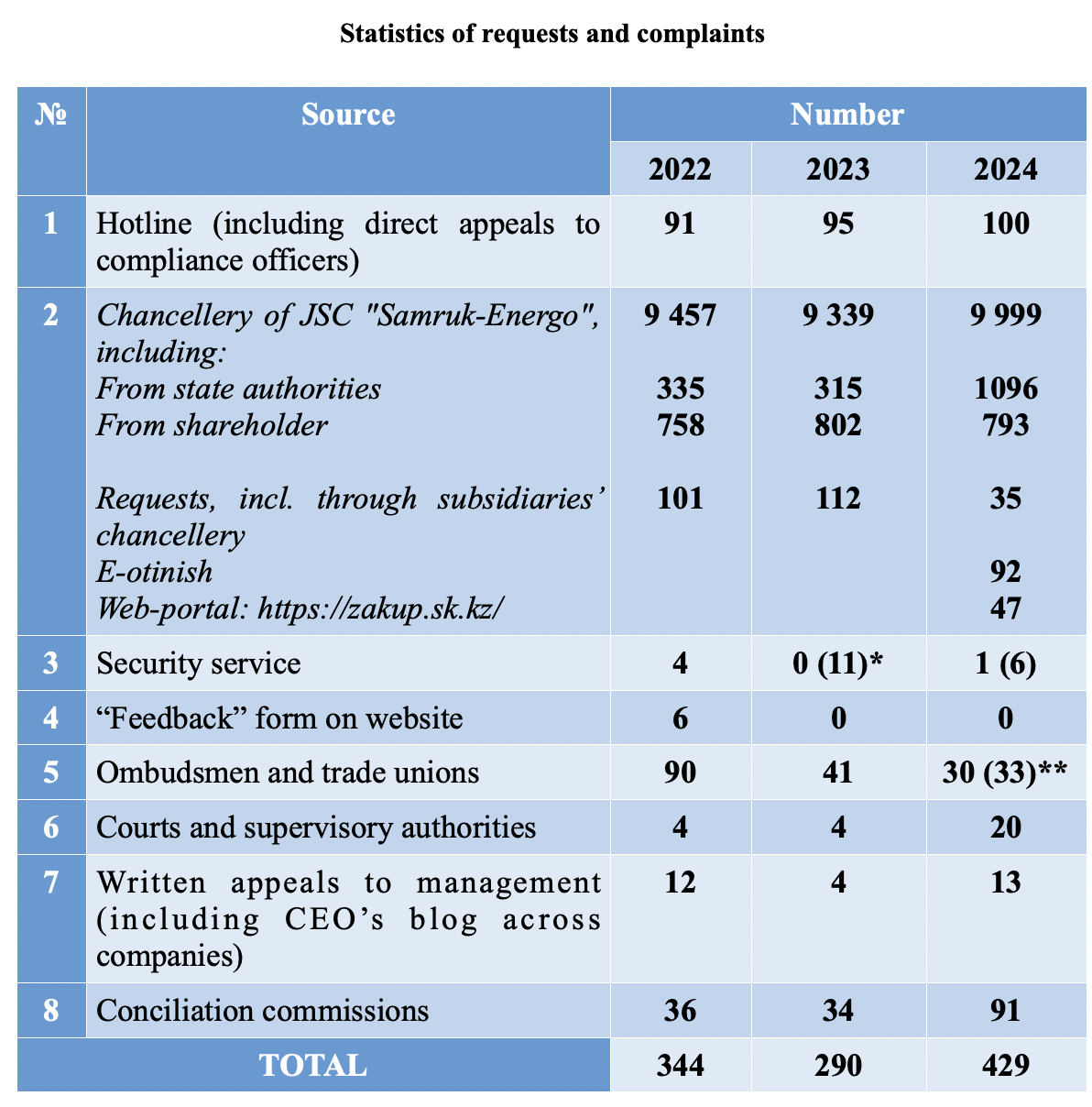

The Company continuously monitors all incoming communications through all feedback channels and annually presents the analysis and monitoring results to the Board of Directors to improve the effectiveness of stakeholder engagement.

The Company analyzes the statistics of inquiries, topics raised by stakeholders, areas of concern, and the timeliness of the Company's responses, and develops recommendations for improving stakeholder engagement.

The results of the analysis contribute to the following objectives:

1) engaging the appropriate level of management in resolving the issues and problems raised, and taking into account suggestions for improvement;

2) analyzing and implementing preventive measures in response to concerns raised by external stakeholders, the public, and individuals;

3) maintaining trust in the Company as a socially responsible energy holding company.

The Company maintains a centralized Complaints and Appeals Database for the Samruk-Energo JSC group of companies, which is used to annually analyze all types of complaints from all subsidiaries and affiliates. The results of the analysis are communicated annually to the Board of Directors.

The majority of appeals were related to issues concerning procurement procedures, salaries, bonuses and other payments, cancellation of disciplinary sanctions, and recalculation of mandatory professional pension contributions.

Applicants were also concerned with matters related to the annulment of orders on disciplinary actions, organization of labor, violations of occupational safety requirements and labor legislation. There were also appeals regarding unethical behavior and abuse of official authority.

Appropriate measures were taken in response to confirmed cases of non-compliance/violations. Confidentiality and anonymity of appeals are guaranteed.

tab177

QUESTIONNAIR

Dear reader!

We would appreciate it if you learn about the Annual report on the Company’s operating results for 2019 and complete the questionnaire on identification of relevant topics in order to cover them in the next “Samruk-Energy” JSC annual report. Your feedback is very important to us!

Link to the questionnaire

tab12

10 principles of the UN Global Compact

In 2011, the Company declared its commitment to follow the 10 principles of the UN Global Compact in its strategy and day-to-day operations and is a member of UN Global Compact.

The company assumed the implementation of following principles:

|

In the field of observance of human rights |

|

|

In the field of labor relations |

|

|

In the field of environmental protection |

|

|

In the field of fight against corruption |

|

As part of its accession to the UN Global Compact, the Company annually publishes Progress Report, which it posts on its website https://www.unglobalcompact.org/

tab14

Women’s empowerment principles

In 2011, Samruk-Energy joined the UN Global Compact, integrating its strategy and daily operations with the Compact's 10 principles.

Specifically, concerning human rights, “Samruk-Energy” JSC group of companies diligently adheres to internationally proclaimed human rights and those established by Kazakhstan's laws. In the realm of sustainable development, the company's primary objective in interactions with employees is to ensure the realization of the right to work, with a society that acknowledges the principle of equal rights and opportunities.

Moreover, the Company is committed not only to developing human rights policies but also to prioritizing key initiatives that promote gender equality in the workplace, thereby improving the rights and opportunities of women.

These principles are intended to assist in the creation and execution of fresh policies and approaches aimed at enhancing women's rights and opportunities across all levels and industries.

The endorsement of these principles by "Samruk-Energy" JSC demonstrates the company's commitment to gender equality principles, recognized as a vital component of sustainable development, and a belief that companies offering equal opportunities to both women and men attain greater success and yield better outcomes.

The principles encompass seven steps that a company can employ to enhance women's rights and opportunities:

1. Establishing active support for gender equality initiatives at the level of the company’s management.

2. Equal opportunities: Inclusion and the absence of discrimination.

3. Health, safety, and freedom from violence.

4. Education and skill enhancement.

5. Development of enterprise, sales methods, and supply chains.

6. Community engagement and societal leadership.

7. Transparency, assessment, and reporting.

Ensuring equal treatment for both men and women is not only a matter of moral correctness but also a smart business decision. The active involvement of women in our company's operations is not only sensible in the present but also holds long-term benefits for our business. A broad approach to sustainability and corporate responsibility, including empowering women as a central goal, will benefit everyone. The seven steps of the 'Women's Empowerment Principles' will guide us in achieving these opportunities.

| Indicator | 2023 | |

|---|---|---|

| Men | Women | |